As Australians seek to control rising energy costs and tackle the damaging impacts of climate change, rooftop solar has boomed.

To manage the variability of rooftop solar – broadly, the “no power at night” problem – we will also see a rapid increase in battery storage.

The question is: what will happen to these panels and batteries once they reach the end of their life?

If not addressed, aging solar panels and batteries will create a mountain of hazardous waste for Australia over the coming decades.

Our research, published recently in the Journal of Cleaner Production, looked at the barriers to managing solar panel waste, and how to improve it.

A potentially toxic problem

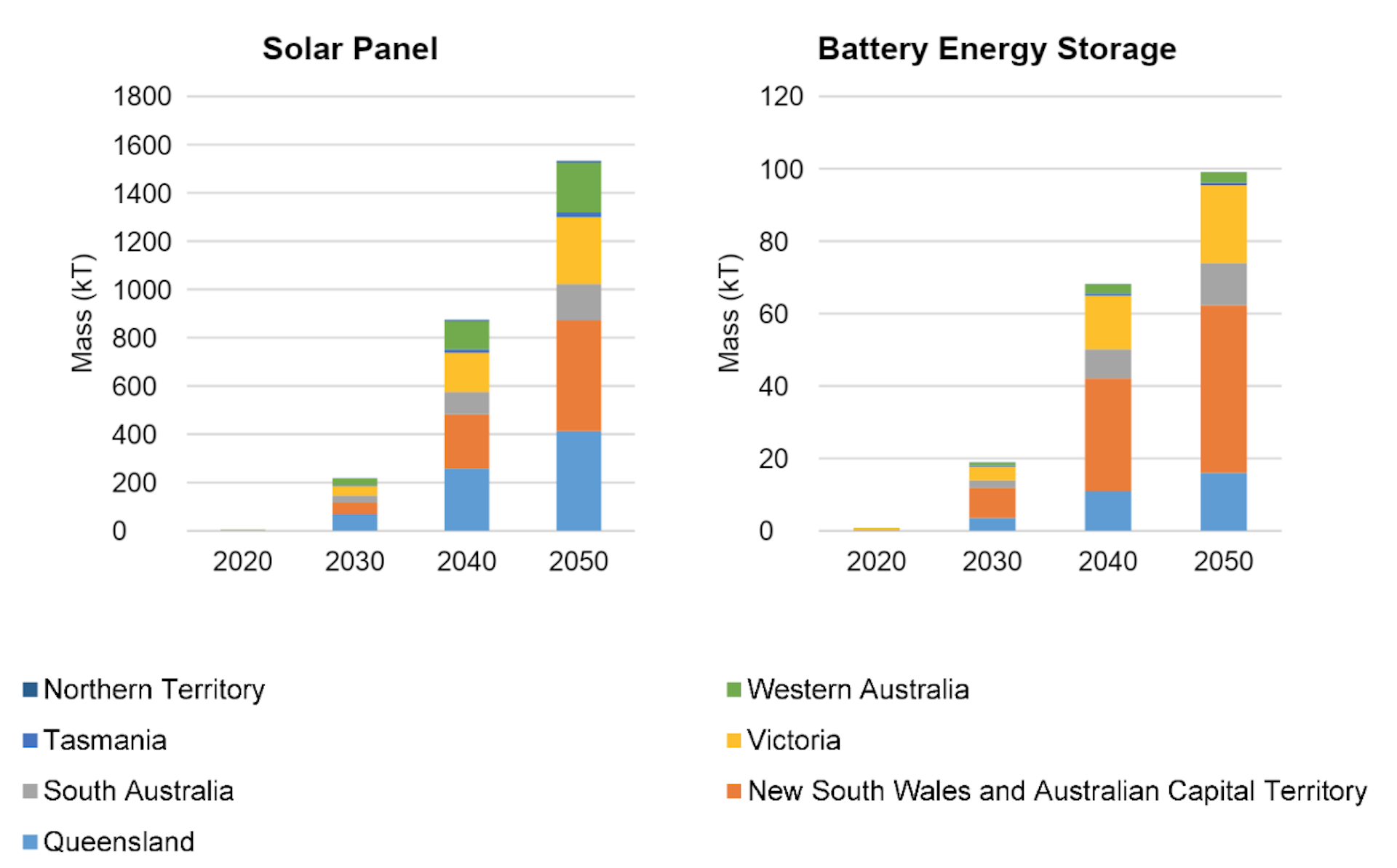

Solar panels generally last about 20 years. And lead-acid and lithium-ion batteries, which will be the most common battery storage for solar, last between five and 15 years. Many solar panels have already been retired, but battery waste will start to emerge more significantly in 2025. By 2050 the projected amount of waste from retired solar panels in Australia is over 1,500 kilotonnes (kT).

Mass of end of life solar panels (a) and battery energy storage (b) 2020-2050. Salim et al. 2019.

Solar panels and batteries contain valuable materials such as metals, glass, ruthenium, indium, tellurium, lead and lithium.

Recycling this waste will prevent environmental and human health problems, and save valuable resources for future use.

Product stewardship

Australia has a Product Stewardship Act, which aims to establish a system of shared responsibility for those who make, sell and use a product to ensure that product does not end up harming the environment or people at the end of its life.

In 2016, solar photovoltaic (PV) systems were added to a priority list to be considered for a scheme design. This includes an assessment of voluntary, co-regulatory and regulatory pathways to manage the waste streams.

Sustainability Victoria (on behalf of the Victorian state government and with the support of states and territories) is leading a national investigation into a system of shared responsibility for end-of-life solar photovoltaic systems in Australia. Our research project has supported the assessment process.

Industries play a crucial role in the success of any product stewardship scheme. As we move into assessing and testing possible schemes, Australia’s PV sector (and other stakeholders) will have critical input.

A preferred product scope and stewardship approach will be presented to environment ministers. Scheme design and implementation activities are tentatively set to start in 2020.

Moving towards a circular economy

Federal and state environment ministers recently agreed to update the National Waste Policy to incorporate the principles of a circular economy.

This approach aims to reduce the need for virgin raw materials, extend product life, maintain material quality at the highest level, prioritize reuse, and use renewable energy throughout the process.

Businesses in Australia currently have little incentive to innovate and improve the recycling rate. By helping implement circular business models such as lease, refurbishment, and product-service systems, we can boost recycling, reduce collection costs and prolong tech lifetimes.

Requiring system manufacturers, importers or distributors to source solar panels and batteries designed for the environment makes both economic and environmental sense. By doing so, recyclers will recover more materials and achieve higher recirculation of recovered resources.

Consumers need to be provided with proper guidance and education for responsible end-of-life management of solar panels and batteries.

Immature domestic recycling capability

Now that China is no longer accepting waste for recycling, Australia needs to rapidly develop its domestic recycling industry. This will also spur job creation and contribute to the green economy.

Given Australia is struggling to recycle simple waste, such as cardboard and plastics, in a cost-effective way, we need to question our capability to deal with more complex solar PV and battery waste.

Australia currently has little capacity to recycle both solar panels and batteries.

And even if China were to suddenly start accepting Australia’s waste – an unlikely proposition – we cannot simply export our problem. As a signatory to the Basel Convention, exporting hazardous materials requires permits.

A previous study suggests half of Australia’s scrap metal is exported for overseas processing, which indicates the lack of incentives for domestic recycling.

Even if we build domestic recycling capability for solar panels and batteries, it will be underused while landfills remain available as a low-cost disposal option.

It’s promising that South Australia and the ACT have banned certain e-waste categories from entering the landfill, while Victoria will implement an all-encompassing e-waste landfill ban from July 1, 2019.

This means any end-of-life electrical or electronic device that requires an electromagnetic current to operate must be recycled.

Creating a circular economy for solar and battery waste will need a strong commitment from policymakers and industry. Ideally, we need to prioritize reuse and refurbishment before recycling.

If we combine sensible policies with proactive business strategy and education to promote recycling rates, we can have a reliable and truly sustainable source of renewable energy in this country.

——

This article is republished from The Conversation, an independent and nonprofit source of news, analysis, and commentary from academic experts. Read the original article.

The article is written by Rodney Stewart (Professor, Griffith School of Engineering, Griffith University), Hengky Salim (Ph.D. Candidate, Griffith University), and Oz Sahin (Senior Research Fellow, Griffith University).

![]()

Comments