Researchers at the Okinawa Institute of Science and Technology Graduate University’s (OIST) Energy Materials and Surface Sciences Unit have found that growing a type of film used to manufacture solar cells in ambient air gives it a growth boost.

The finding, which could make manufacturing solar cells significantly cheaper, was published in Chemistry of Materials.

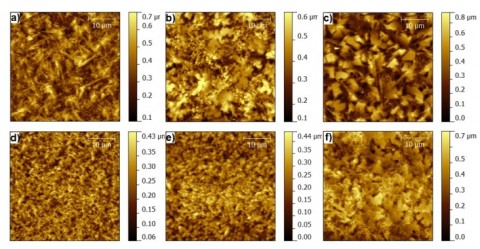

a) 105°C in air b) 115°C in air, c) 125°C in air, d) 105°C in Nitrogen, e) 115°C in Nitrogen, and f) 125°C in Nitrogen. Grain sizes on perovskite films are larger when prepared in air between 105 to 125 degrees centigrade than in a nitrogen atmosphere. Credit: OIST

a) 105°C in air b) 115°C in air, c) 125°C in air, d) 105°C in Nitrogen, e) 115°C in Nitrogen, and f) 125°C in Nitrogen. Grain sizes on perovskite films are larger when prepared in air between 105 to 125 degrees centigrade than in a nitrogen atmosphere. Credit: OIST

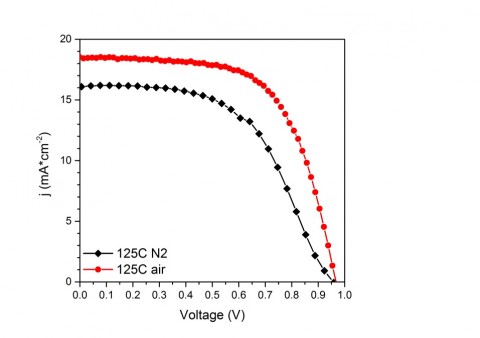

Voltage curves of two perovskite solar cells annealed in air (red) and Nitrogen (black). The average power conversion efficiency for 6 solar cells annealed in air was 11.1%. In a nitrogen atmosphere it was 8.5%. Credit: OIST

Voltage curves of two perovskite solar cells annealed in air (red) and Nitrogen (black). The average power conversion efficiency for 6 solar cells annealed in air was 11.1%. In a nitrogen atmosphere it was 8.5%. Credit: OIST

The type of material is called Perovskite. Since the discovery of its application in harvesting light for electricity in 2009, research on solar cell application has skyrocketed. Fabrication techniques are being developed around the world to improve their power conversion efficiencies. The OIST study gives perovskite solar cells another shot in the arm by making the materials easier to mass produce.

Earlier studies had concluded that exposing perovskite films to ambient air was detrimental because moisture reacted with perovskite, which degraded over time. It was therefore believed the material had to be prepared using a heat treatment called annealing in a water-free environment.

OIST researchers set out to investigate the effects of moisture on perovskite formation during 45 minutes of annealing, at temperatures between 105 and 125 degrees centigrade. They grew a type of perovskite that has been shown to work better for solar cells. Then, they compared the Perovskite film’s formation in a nitrogen atmosphere with its formation in humid air and found that the films actually receive a growth improvement resulting in larger grain sizes than usual in the presence of moisture. The film grows slowly, so larger grains can form.

“Larger grain sizes mean the crystals on the film is more continuous, and the electrons passing through the film face fewer interruptions,” said Sonia Ruiz-Raga, the study’s first author.

Larger grains make perovskite solar cells more efficient. The highest efficiency achieved by the study was 12.7 percent. While other teams have achieved higher efficiencies, the OIST result ensures that future industries need not invest in expensive climate control machinery to keep the moisture down to one part per million. Air annealing costs nothing.

Overall, 12.7 percent efficiency is by no means the ceiling for this fabrication technique and it is possible to obtain even larger grain sizes. While global research and development to boost solar cell efficiencies continue, these results potentially provide a way to jumpstart industry.

References:

Publication: Sonia R. Raga, Min-Cherl Jung, Michael V. Lee, Matthew R. Leyden, Yuichi Kato, Yabing Qi. Influence of Air Annealing on High Efficiency Planar Structure Perovskite Solar Cells. Chemistry of Materials, 2015

Story: Solar Cells Get Growth Boost | Okinawa Institute of Science and Technology – OIST — March 4, 2015

Comments