Organic solar panels are inexpensive and friendly to the environment. They are flexible and light, but their efficiency is lower compared to conventional, rigid silicon-based solar panels.

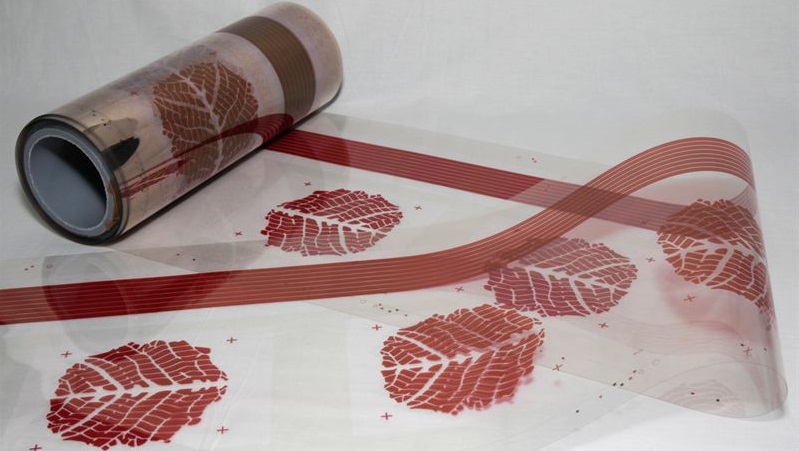

These solar panels are manufactured with printing machines based on conventional printing methods using the roll-to-roll method, which enables the rapid mass production of the products: the printing machine can produce up to 100 metres of layered film per minute.

Organic photovoltaic cells or OPV cells manufacturing process is affordable; the material consumption is low, and after use, the OPV panels can be recycled. The market is developing, with a market breakthrough expected within three years. The panels have an operating life of of a few years which is enough for many applications.

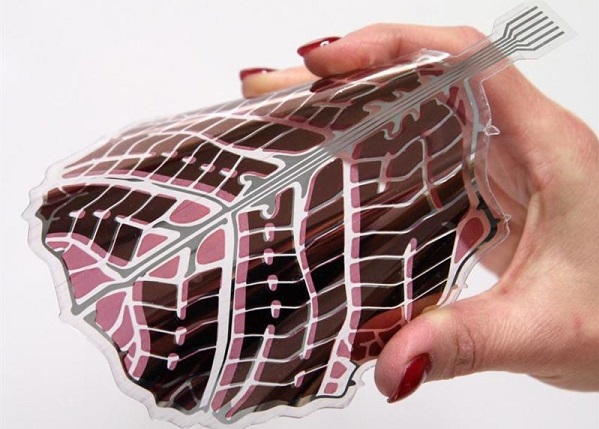

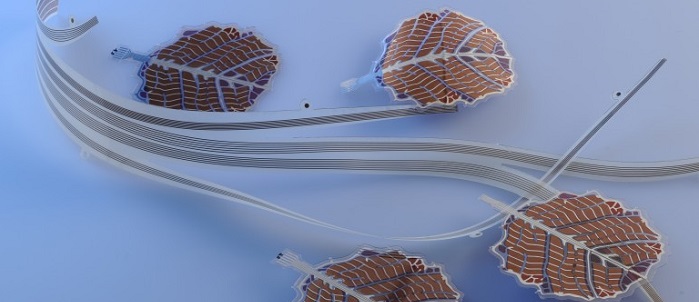

VTT has developed a mass production method allowing the manufacturing of decorative, organic solar panels. Active surface of a one leaf is 0..0144 m2 and includes connections and a decorative part. Graphics can be printed to improve the visual appearance. Photo Credit: Antti Veijola.

VTT has developed a mass production method allowing the manufacturing of decorative, organic solar panels. Active surface of a one leaf is 0..0144 m2 and includes connections and a decorative part. Graphics can be printed to improve the visual appearance. Photo Credit: Antti Veijola.

Scientists have now developed and utilized a mass production method based on printing technologies allowing the manufacturing of decorative, organic solar panels.

The new mass production method enables to create interior design elements from organic solar panels (OPV, organic photovoltaics) harvesting energy from interior lighting or sunlight for various small devices and sensors that gather information from the environment.

The panels can, for example, be placed on windows and walls and on machines, devices and advertisement billboards. Until now, it has only been possible to pattern OPV panels into a form of stripes.

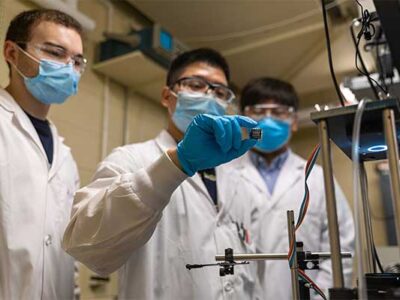

Researchers are also studying the feasibility of printing technology in the mass production of solar panels made from inorganic perovskite materials.

Comments