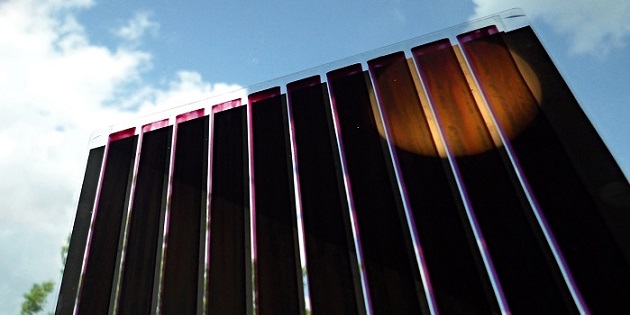

Researchers incorporate ultra-thin glass in the printing process of organic solar modules to protect the components thereby making them last longer.

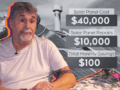

Organic solar modules–as recap–are polymer-based thin film solar modules with the advantage of being lightweight, flexible, cheap, and easily disposable over silicon solar modules.

The only issue is that the operating lifespan of these organic solar modules are very short due to their vulnerability to environmental stress. They are relatively permeable to humidity and oxygen.

We’ve discussed many exciting developments for organic solar modules recently on PV-Buzz; and this development improves the likelihood that these modules may one day be more competitive–if not surpass–conventional solar modules. In order for this to be the case, there must be a way to make these modules fracture-resistant and extremely strong.

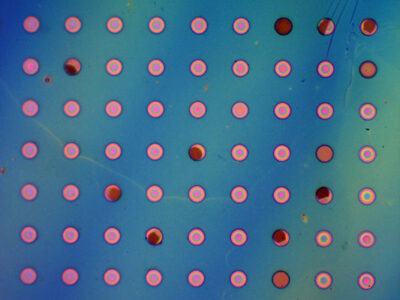

So researchers at the Fraunhofer Institute for Applied Polymer Research IAP in Potsdam, Germany are working on using flexible glass (specialized glass from Corning Inc.) as a carrier substrate in which these modules are embedded. A process that may help protect the flexible and very fragile organic solar modules.

“Glass is not only the ideal encapsulating material, it also tolerates process temperatures of up to 400 degrees,” explains Danny Krautz, project manager in the Functional Materials and Components research section at IAP.

The researchers are doing their best to maintain the same uniqueness of producing (printing) these organic solar modules in rolls stacked sheet-by-sheet.

They advice that the technology would need to be modified at many points for the process to meet the demands of industrial applications.

But they are confident that long-lived, robust, high-performance organic solar modules can be fabricated with this technology for use in a wide range of applications – from tiny solar cells in mobile phones to large-scale photovoltaic modules.

Comments