- The team at Friedrich-Alexander-Universität Erlangen-Nürnberg, in collaboration with the Helmholtz Institute, has achieved a groundbreaking efficiency of 14.46% in organic solar modules.

- This new record surpasses the previous best of 13.1%, demonstrating the potential of organic photovoltaics to compete with conventional silicon solar cells.

- The development promises more flexible, lightweight, and environmentally friendly solar energy solutions.

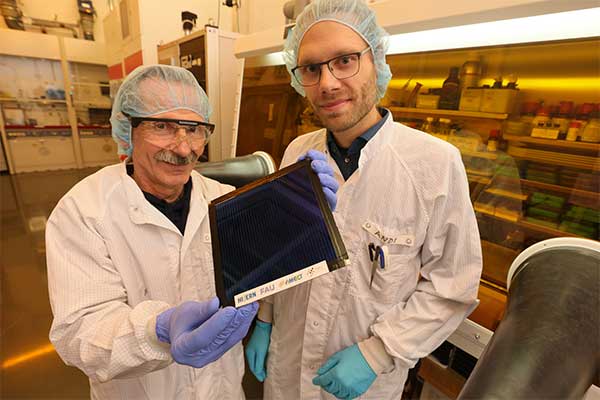

Dr. Andreas Distler, a scientist at Friedrich-Alexander-Universität Erlangen-Nürnberg (FAU), has constructed the most efficient organic solar module to date in close cooperation with the Helmholtz Institute Erlangen-Nürnberg for Renewable Energy (HI ERN), which is part of Forschungszentrum Jülich.

It achieves a new certified* record efficiency of 14.46 percent, beating the previous world record for organic photovoltaic modules (OPV) of 13.1 percent set by Waystech. This proves that organic photovoltaics can be established as an alternative to silicon & Co. in the long term.

In search of the perfect material

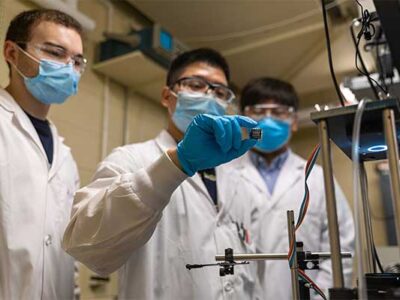

Solar energy is one of the great hopes when it comes to the energy transition. Research in this future-oriented field is correspondingly extensive. One of the major challenges: finding the perfect material.

In terms of efficiency, silicon is currently hard to beat.

However, it has serious disadvantages: it is too rigid and heavy and difficult to recycle. Researchers led by Prof. Christoph Brabec, Director at the Helmholtz Institute Erlangen-Nuremberg (HI ERN) and Professor of Materials for Electronics and Energy Technology at FAU, are therefore pursuing a different approach: they want to conquer the market with organic photovoltaics (OPV).

The advantage of OPV: the modules can be flexible and also transparent, can be integrated into windows and facades, used indoors or as roofing in fields, for example in growing tunnels. They also have a much more favorable ecological footprint – the manufacturing processes are more environmentally friendly and the material is easier to recycle.

“Solution-processed organic photovoltaics is becoming an important component of a photovoltaic strategy that focuses on the speed of capacity expansion and integration capability. Similar to perovskites, it enables photovoltaic applications beyond the gigawatt fields in desert regions. Organic photovoltaics can thus make a sustainable contribution to bringing the production of photovoltaics back to Europe,” explains materials scientist Christoph Brabec.

The weakness of the technology to date lies in its efficiency: while silicon modules already achieve efficiencies of over 20 percent, OPV researchers were still struggling to achieve double-digit results just a few years ago. It is therefore all the more pleasing to see that new records are gradually being set in this area: Christoph Brabec’s team has managed to increase efficiency to 14.46 percent.

Three parameters provide the necessary efficiency boost

Dr. Andreas Distler, who achieved the coup, worked on three parameters:

“Firstly, we used improved active materials. But it was at least as important for us to reduce the inactive areas on such a module – to do this, we further optimized the laser structuring process, which divides the module surface into individual solar cells and interconnects them electrically – the trick here is to keep the laser lines as thin as possible, because this area on the module cannot generate electricity later,” explains the FAU researcher. “Finally, together with our colleagues from the Georg Simon Ohm University of Applied Sciences in Nuremberg, we used computer simulations to develop a more homogeneous coating. These are all small efficiency boosters which, when combined, increase efficiency by one percentage point.”

“For the successful cooperation between FAU and HI ERN, as part of Forschungszentrum Jülich, this current world record is a particularly visible milestone: it once again underlines the importance and success of the Solar Factory of the Future, which both institutions operate jointly at the Energy Campus Nuremberg,” adds Christoph Brabec. “With the Solar Factory of the Future, a unique process infrastructure has been created with the financial support of the Bavarian Ministry of Economic Affairs, with which we are able to realize our technical developments and breakthroughs within the Innovation platform Solar TAP can be transferred very efficiently and quickly to the industry. We are also achieving similarly impressive results in the development of printed perovskite solar cells as well as fully printed tandem cells.”

*The record efficiency was certified by Fraunhofer ISE (CalLab PV Cells) in Freiburg.

—

This article has been adapted from source material published by Helmholtz-Institut Erlangen-Nürnberg.

Comments