Establishing a Baseline for Safety

With 2014 NEC adoption in full swing—it has been implemented in 22 states as of April 14, 2015—many are anticipating what the next version of the code will hold for the PV industry. The highest-profile addition to the photovoltaics section of 2014 NEC was the rapid shutdown requirement outlined in 690.12, which arguably became the most debated revision to that edition.

However, the proposed 2017 NEC may drastically modify that rule to effectively require shutdown at the module level, which would have a dramatic impact on how systems are designed and installed moving forward. While this change was certainly developed with first responder safety in mind, it has left many to wonder if module-level shutdown really is safer.

In order to measure an increase in safety, there should be a baseline for comparison. What data exists to demonstrate that safety increases are required? What past incidents involving first responder injury could have been avoided with module-level shutdown? The number of PV-related fatalities of first responders is zero. According to the National Institute for Occupational Safety and Health database, between 1984 and 2013, there have been seven first responder deaths due to electrocution, and all were related to AC medium-voltage overhead or downed power lines. Without a basis for comparison, how can it be said that we have achieved a safety improvement? How could we convince ourselves that this is worth the effort, when there are other, more effective means of ensuring the safety of first responders without providing a false sense of security?

As is often the case with the evolution of PV in North America, we can look to European markets to offer some level of experience and guidance. A German study conducted by the Federal Ministry for Economic Affairs & Energy, TÜVRheinland, and Fraunhofer was completed in March 2015 and titled “Assessment of the Fire Risk in Photovoltaic Systems and Elaboration of Safety Concepts for Minimization of Risks.” The study concluded that PV systems do not pose any particular threat to fire department personnel, provided they comply with safety clearances just as with any other voltage-carrying electrical equipment. Moreover, the vast majority of European PV systems do not utilize module-level electronics and there has never been a governing body that has enforced a code mandating module-level shutdown.

An additional report issued by Fraunhofer, Europe’s largest application-oriented research organization, was completed in May 2015 and titled “Recent Facts about Photovoltaics in Germany.” The report offered updated statistics regarding first responder safety and revealed a considerably successful record. With more than 1.4 million PV plants installed in Germany, to date no firefighter has been injured by PV power while putting out a fire.

This significant fact becomes even more telling when you consider it was achieved in a market that does not mandate rapid shutdown at all, let alone module-level shutdown. The report goes on to state, “Comprehensive training courses for the fire brigade could eliminate any uncertainties firefighters may have. As with every electrical installation, depending on the type of electric arc it is also possible to extinguish a fire using water from a distance of one to five meters. Based on investigations to date, all of the claims stating that the fire brigade could not extinguish a house fire due to the PV system have been found to be false.” So as 2017 NEC is being drafted and debated we must ask ourselves: who is driving the revisions to 690.12 and what is their motivation?

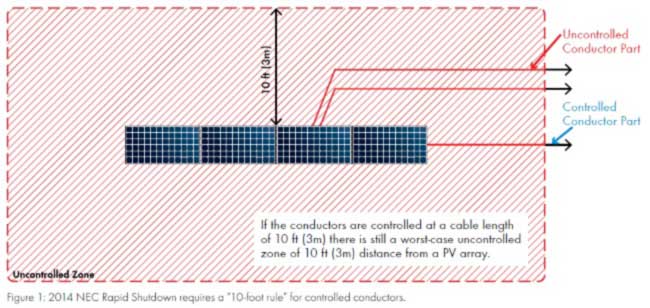

2014 NEC 690.12 Defined

The current code is fairly inclusive of all PV architectures and technologies and prescribes a keep-out zone outside of which the PV system voltages must be reduced to less than 30 volts in 10 seconds. This is commonly known as the “10-foot rule.”

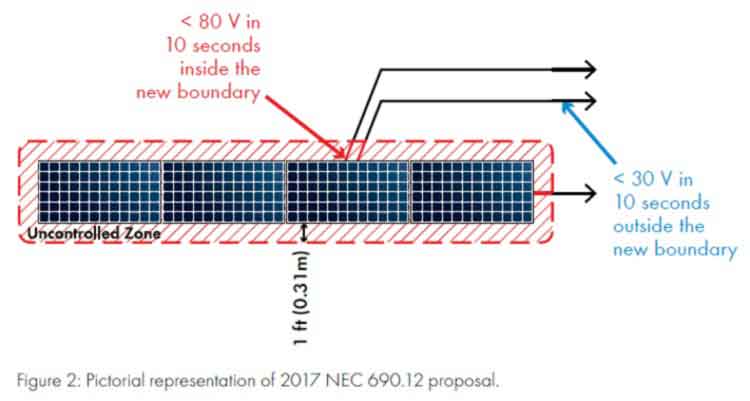

2017 NEC 690.12 Proposed Revision

The 2017 NEC language proposes reducing the 10-foot keep-out zone to a one-foot boundary, which is a minor change of the wording that results in a major change in the way PV systems will be designed and built. However, on top of this, an additional requirement of this section is already generating concern throughout the industry due to the inclusion of an additional 80V limit stipulation inside the one-foot boundary, effectively requiring a module-level disconnect.

Safety by the Numbers

Safety is always the number-one priority for any PV installation, but it is not clear that the new 80V limit will result in an increase in first responder safety. It could, however, decrease the safety of installers. The 80V limit is somewhat arbitrary and was chosen primarily because it is greater than most module Voc’s rather than corresponding to a recognized safety limit. It is also, coincidentally, the threshold at which module-level electronics manufacturers can comply using currently available solutions. According to UL 1310, the safe voltage in dry conditions is 60V and 30V in wet conditions (also 2014 NEC Chapter 9, Table 11(B)). Additionally, UL 62109-1 and 2014 NEC outline 240VA as the safe limit (energy hazard), which is a lower power level than many modules in the market today.

The 2017 NEC removes the 240VA reference, but if this reference is for safety, why remove it and add an 80V limit?

If first responders need to cut a hole in a roof and come into contact with a module in the process, then they would potentially be exposing themselves to a higher voltage than prescribed by UL or current NEC. Modules are typically spaced less than a quarter-inch apart and, even though the wiring between modules may not be conducting, the modules will remain at open circuit voltage. To cut through a roof in an area where PV exists would mean chopping through a module, potentially giving module power a path to ground and exposing firefighters to more than 300VA.

However, international best practices among first responders suggest they would not only avoid chopping through a module, they would avoid the array entirely. So in essence the proposed code revision makes a case for a scenario that will likely not exist.

Safety as a Reality, Not an Idea

The 80V limit is not sufficiently small enough to avoid restart arcs and even an attenuated line voltage of a single panel can provide enough concentrated power to cause a fire ignition. According to interviews conducted by DNV GL, a world-renowned testing and advisory service provider, interviews of fire service personnel indicate that they will not change their firefighting practices with the implementation of the 80V limit because it could still be hazardous inside the array. More importantly, they don’t need to enter the array if adequate space is provided on the roof for safe egress and for roof ventilation access.

Furthermore, trusting rapid shutdown to reliably work without taking other personal safety measures could lead to perceived safety and complacency due to familiarity. With the sheer number of systems already installed prior to 2014 NEC, how will a first responder know that a PV system is equipped with rapid shutdown, module-level shutdown or neither? The options would be to assume that every system is equipped with module-level shutdown, which creates a false sense of security, or to assume that no PV system is 100% safe in the event of a fire. Even with signage requirements, the safest best practice would advocate that first responders avoid the PV system entirely.

New building codes require accessible walkways on roofs, which would provide a safe place for first responders to ventilate them. Even this may not be relevant because best practices advise them to NOT open up burning roofs or even step onto burning roofs unless it is absolutely critical. In fact, many firefighters report they are reluctant to go on the roof of a burning building, residential in particular, to punch holes for ventilation because of the very lightweight building methods and materials used in modern construction, which burn rapidly and can essentially create an unsupported roof.

We must also consider the safety of PV installers, who spend significantly more time on the project sites than first responders. An 80V limit would mean that module-level power electronics of some kind would have to be used to reduce the voltages to this level. However, the best way to improve the reliability of a system (and thereby reduce installer service visits) is to reduce the number of components in it.

Module-level electronics manufacturers have claimed much higher reliability statistics than string inverters but real-world statistical validation does not support those claims. Even if we consider module-level power electronics to be equal in reliability to string inverters, the number of opportunities for failure increases and statistically more failures will occur. This causes two problems: the general reliability of the system is reduced (affecting the owner, installer and off-taker) and those tasked with operations and maintenance will find themselves on-site more often.

If the industry is forced to move to a more aggressive or even module-level shutdown–which will not change the firefighters’ behavior–on the premise that it will protect them, where is the concern for installer safety five,10 or 15-plus years down the road when they are on rooftops swapping out failed or worn out module-level devices?

A very real risk comes with this increased time on the roof and it will be installers and service personnel who will be exposed to a higher potential for falls, which is a documented dangerous situation.

According to the U.S. Bureau of Labor Statistics, a total of 20,498 occupational fatalities occurred in the construction industry from 1992 – 2009. Of these deaths, nearly one-third (6,591) were attributed to fall injuries, with 2,163 fatalities resulting from roof falls.

“Fatalities from falls are the number one cause of workplace deaths in construction. We cannot tolerate workers getting killed in residential construction when effective means are readily available to prevent those deaths. Almost every week, we see a worker killed from falling off a residential roof.” -Dr. David Michaels, Assistant Secretary of Labor for Occupational Safety and Health

Even with an 80V limit, there are still circumstances where a first responder could be exposed to a shock hazard above levels deemed to be safe. Therefore, there still needs to be a keep out zone for first responder guidance. The UL standard currently proposed does not verify that rapid shutdown systems will function in the event of a fire. If there is reason to get on the roof at all, it’s also best to stay in the walkways and keep a safe clearance from the array. Thus, we will not improve the safety of rooftop PV systems with the proposed change to 690.12, but will only achieve an increase in system complexity, cost, maintenance and installer risk.

Ensuring Transparency and an Equal Voice for all PV Professionals

It is imperative that all relevant stakeholders in the PV industry take heed of the current direction of this code and become involved in the discussion and panel activities. We have an obligation to include solar installers, engineers, service personnel, trade organizations and equipment manufacturers of all technology architectures to ensure that a diverse cross section of the industry is represented instead of just a select few manufacturers who stand to gain the most from the code revision.

Our goals throughout these exchanges should continue to hold the safety of first responders paramount while avoiding the creation of perceived danger (and perceived safety) that cannot be supported by statistical validation.

We must also avoid the adoption of a code that essentially mandates the usage of a specific PV technology with a questionable effect on safety and a huge impact on the future potential of rooftop PV installations. As part of this review process, it is important to take note of the PV industry co-sponsors of this code change (see page 5855 of NFPA public comments) and ensure that their motives are transparent and truly reflect a desired outcome of safety. As a matter of transparency, three out of the four PV industry co-sponsors represent module-level electronics suppliers, while many of the PV industry’s largest and longest tenured equipment manufacturers are absent from this group and oppose the revision.

The module-level electronics sponsors of this code revision are part of a small group of suppliers who can currently meet the requirements of the proposed 2017 NEC revision, thereby creating an economic boon for themselves while the health and growth of the industry at large suffers because many competitive (and equally safe) technologies are essentially blocked from the market. We mustn’t let the manufactured perception of danger dictate code revisions that purport to increase safety when no statistical evidence or technological justification exists to support those claims.

This article has been published here by the PVBUZZ team from the original article written by Hannes Knopf, Head of Commercial Business and Portfolio Strategy, SMA Solar Technology, Dr. Michael Mendik, General Manager U.S. Technology, SMA America Production, Matt Marx, Strategic Marketing Manager and SMA Solar Technology. It was edited for publication on Solar Power World Online by Kathie Zipp.

Comments