Unlike traditional silicon solar cells, organic polymer solar cells (PSCs) may never cover the hillsides of a megawatt solar farm. But, these lightweight, flexible cells show potential to provide solar power to remote microwatt sensors, wearable technology and the Wi-Fi-connected appliances constituting the “internet of things.”

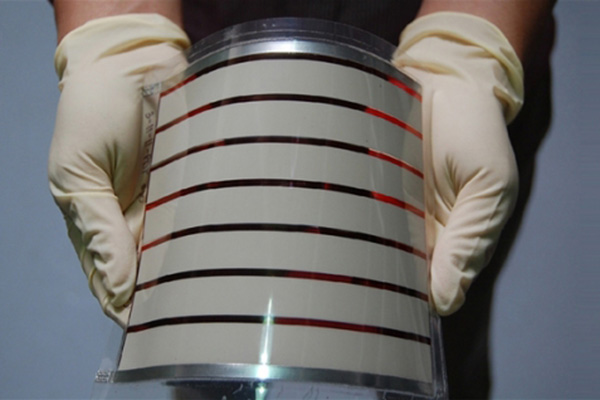

PSCs use organic polymers to absorb light and convert it to electricity. While PSCs cannot match the durability or efficiency of inorganic solar cells, the potential to mass-produce nontoxic, disposable solar panels using roll-to-roll production makes them attractive for additional applications.

In a paper published this week in the Journal of Renewable and Sustainable Energy, from AIP Publishing, Paul Berger and Minjae Kim of Ohio State University review the latest advances and remaining challenges in PSC technology.

Research into PSCs has grown rapidly over the last two decades, generating increasing numbers of publications and patents. This emerging technology, however, is unlikely to replace traditional inorganic solar cells.

Instead, Berger sees PSCs as complementary. They can bypass the high-voltage transmission lines and provide electricity to point-of-use devices that would otherwise require toxic batteries.

For example, PSCs could power freshness sensors on food packaging simply using the overhead lights in grocery stores. Furthermore, they could go beyond store inventory control, and tie into a “smart kitchen” to reduce food waste and automate grocery lists. “PSCs have this ability to be flexible, because they basically are plastics, so you can put them on backpacks, jackets and even coffee creamer — a whole range of things where it’s at the point of use,” said Berger. “It’s a disruptive business model.”

The polymers can be dissolved in solvents and printed onto a flexible backing using affordable roll-to-roll production, making this technology especially attractive. “This printing press is not unlike the one for printing your Sunday newspaper, but instead of three primary colors and black, you’re printing the four or five different layers needed for the solar cell, diodes and transistors,” Berger said. Long rolls of solar cells also open up new applications, such as wrapping vehicles or covering building facades and windows. Berger cautions, however, that certain expensive PSC raw materials, namely indium tin oxide and fullerenes, which have proved challenging to replace, may limit near term affordability.

Longevity is another issue because the polymers and reactive metal cathodes oxidize when exposed to water and oxygen. “They tend to degrade fairly quickly,” Berger said, making it necessary to encapsulate the solar cells for protection. This encapsulation can be very effective on glass, but is more challenging on flexible surfaces, like potato chip bags.

In the lab, PSC efficiency reaches about 13 percent, which is far from the 20 percent efficiency of commercial solar panels. PSCs that use P3HT:PCBM polymers, introduced in 2002, are the standard “workhorse” design and yield about 3.5 percent efficiency. Recent advances in chemistry, geometry, and the development of tandem solar cells that stack multiple layers together have made this greater efficiency possible.

A handful of companies in the U.S. and Europe are working to bring viable PSCs to market. If successful, then PSCs could establish their own niche apart from silicon solar cells, powering all manner of remote devices.

Comments