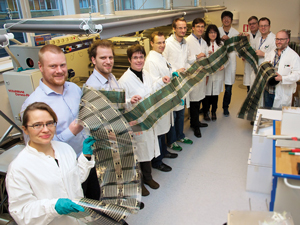

A team of specialists in renewable energy technologies with focus in organic solar cell modules at the Technical University of Denmark have successfully developed a rapid, scalable and industrially viable protocol to manufacture large sheets of flexible organic solar cells.

This breakthrough engineered application of roll-to-roll processing is a huge step forward for renewable energy technology.

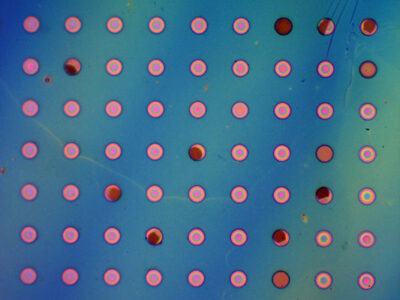

The manufactured tandem OPV modules are made up of 14 layers which are quickly printed, coated or stacked on each other using this relatively inexpensive, scalable and high yield protocol (see publication for more).

Why is this important?

As recap, organic photovoltaic (OPV) solar cells are polymer-based thin film solar cells with the advantage of being lightweight, flexible, cheap, and easily disposable over conventional solar cells.

Researchers have been working on finding different ways to improve on the efficiency, and durability of OPVs–a major limitation towards its commercialization.

‘The performance from these scalably fabricated devices has a long way to go to achieve commercial viability. But this work clearly shows that the process itself is feasible and has the potential for genuine market impact’ states Seth Darling, an expert in solar energy conversion at Argonne National Laboratory, United States.

Comments