Silicon absorbers primarily convert the red portion of the solar spectrum very effectively into electrical energy, whereas the blue portions are partially lost as heat. To reduce this loss, the silicon cell can be combined with an additional solar cell that primarily converts the blue portions.

Teams at HZB have already acquired extensive experience with these kinds of tandem cells. A particularly effective complement to conventional silicon is the hybrid material called perovskite. It has a band gap of 1.6 electron volts with organic as well as inorganic components.

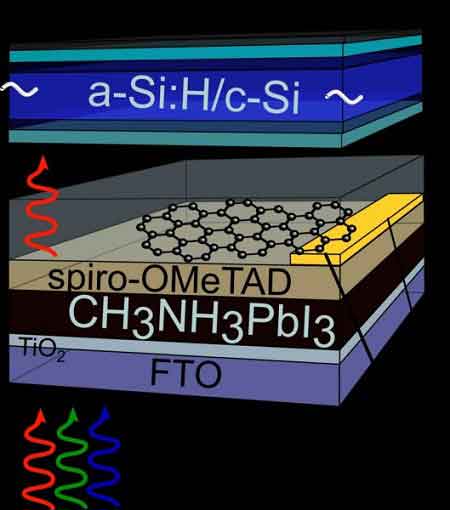

The perovskite film (black, 200-300 nm) is covered by Spiro.OMeTAD, Graphene with gold contact at one edge, a glass substrate and an amorphous/crystalline silicon solar cell.

The perovskite film (black, 200-300 nm) is covered by Spiro.OMeTAD, Graphene with gold contact at one edge, a glass substrate and an amorphous/crystalline silicon solar cell.

Credit: F. Lang / HZB

However, it is very difficult to provide the perovskite layer with a transparent front contact. While sputter deposition of indium tin oxide (ITO) is common practice for inorganic silicon solar cells, this technique destroys the organic components of a perovskite cell.

Graphene as transparent front contact:

Now a group headed by Prof. Norbert Nickel has introduced a new solution. Dr. Marc Gluba and PhD student Felix Lang have developed a process to cover the perovskite layer evenly with graphene. Graphene consists of carbon atoms that have arranged themselves into a two-dimensional honeycomb lattice forming an extremely thin film that is highly conductive and highly transparent.

Fishing for graphene:

As a first step, the scientists promote growth of the graphene onto copper foil from a methane atmosphere at about 1000 degrees Celsius. For the subsequent steps, they stabilise the fragile layer with a polymer that protects the graphene from cracking. In the following step, Felix Lang etches away the copper foil. This enables him to transfer the protected graphene film onto the perovskite. “This is normally carried out in water. The graphene film floats on the surface and is fished out by the solar cell, so to speak. However, in this case this technique does not work, because the performance of the perovskite degrades with moisture. Therefore we had to find another liquid that does not attack perovskite, yet is as similar to water as possible,” explains Gluba.

Ideal front contact:

Subsequent measurements showed that the graphene layer is an ideal front contact in several respects. Thanks to its high transparency, none of the sunlight’s energy is lost in this layer. But the main advantage is that there are no open-circuit voltage losses, that are commonly observed for sputtered ITO layers. This increases the overall conversion efficiency. “This solution is comparatively simple and inexpensive to implement,” says Nickel. “For the first time, we have succeeded in implementing graphene in a perovskite solar cell. This enabled us to build a high-efficiency tandem device.”

Reference(s):

Publication: Felix Lang, Marc A. Gluba, Steve Albrecht, Jörg Rappich, Lars Korte, Bernd Rech, Norbert H. Nickel. Perovskite Solar Cells with Large-Area CVD-Graphene for Tandem Solar Cells. The Journal of Physical Chemistry Letters, 2015

Story: Graphene as a front contact for silicon-perovskite tandem solar cells | Helmholtz-Zentrum Berlin für Materialien und Energie — October 2, 2015

Comments