This question is asked by many potential buyers. Battery storage systems available on the market differ considerably in terms of safety, price, performance, and, hence, economic efficiency.

At Intersolar, the world’s leading exhibition for the solar industry in Munich, the KIT will now present its latest research findings as to how efficient batteries should be designed and provide information on the reliable assessment of the performance of storage systems.

Storage systems differ considerably! Even when focusing on a single technology, such as lithium-ion technology, major differences remain. The exhibits at the booth (B1.631) of KIT at the Intersolar from June 10 to 12, 2015 in Munich will illustrate relevant aspects.

Good and bad types of cell connection and their direct impact on the performance will be presented as well as quality requirements in the assembly of battery modules. An industry robot at the booth will demonstrate the important role of spot welding. The performance of storage systems is based on the elaborate interaction of all individual components.

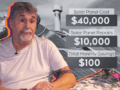

“Thanks to our daily research work, we have an extremely good overview of the market,” Dr. Andreas Gutsch of the Competence E Project of Karlsruhe Institute of Technology (KIT) says. Performance tests are standard practice at KIT. They are carried out using own laboratory prototypes and nearly all commercially available lithium-ion cells that might be applied in stationary storage systems for comparison purposes. Experience shows that the performance of the various cells differs over a wide range. Compared to photovoltaic modules, the range of performance of storage systems is extremely large. “The customer is left alone. Nearly all tested cells are available in systems on the German market. Prices of the storage systems vary largely, but they do not have anything to do with the economic efficiency and performance. As regards the price-performance relation, the market is completely intransparent and some of the systems sold are not worth their money in terms of performance.”

It takes around 3000 charge and discharge processes until the profits produced by a stationary storage system balance out the investment costs. Only after 3000 full cycles until the end of the battery service life do storage systems operate profitably. KIT performance tests, however, revealed that some cells lose 30% of their capacity after 1000 full cycles already. With these capacity losses, the stationary storage systems can no longer be operated in an economically efficient manner.

Apart from cycle stability, internal resistance of the cells determines the performance of a storage system. Aging of batteries, hence, is reflected by two major features: Capacity decreases or internal resistance of the cells increases. With increasing internal resistance, more electrical energy in the form of heat is lost. Consequently, the increase in internal resistance is a parameter reflecting the increase in battery warming with battery aging. “If you would like to know whether a battery manufacturer offers good systems, do not only ask for cycle stability, but also for the increase in internal resistance with aging and the handling of this problem,” Gutsch emphasizes. “This aspect should be considered in the thermal management of the battery.”

The efficiency of a complete system is determined by the whole chain from the solar generator to the battery, inclusive of the battery inverter, to the consumer. “Very good battery systems with lithium-ion cells reach efficiencies in the range of 99% today. This is the basis of an excellent total system efficiency. All additional components in the system reduce efficiency,” explains Dr. Olaf Wollersheim, who heads the Competence E Project together with Gutsch. It is not only important to use highly efficient lithium-ion cells, but also to dimension the overall system adequately for the specific application. An optimum system efficiency is achieved, if the performances of the individual components are adjusted precisely. Apart from system architecture, battery efficiency is influenced by the cell and battery module connection technologies. “Here, commercial systems differ considerably: An expensive system with best-in-class cells may quickly become a middle- or low-class storage system as a result of bad connection technologies. Home storage systems may be economically efficient today and electricity purchase costs may be reduced by increasing own consumption from photovoltaic systems. Everything depends on the right system for the respective application.”

The Competence E project covers all economically relevant research aspects from the battery material to the electric storage system in a way that is unique in Germany. With an open technology platform for electric energy storage systems, the systemic approach is aimed at developing industrially applicable solutions and their production methods. Thanks to integration along the chain of values added, battery systems with an energy density of 250 Watt-hours/kg are to be manufactured at costs of EUR 250 per kilowatt-hour by 2018. This will be an important step towards the energy turnaround and reaching climate protection objectives: Increased storage capacity of stationary storage systems to compensate the fluctuation of renewable energies and enhance the range of electric vehicles for increased acceptance.

Reference(s):

Story: Intersolar: Finding Safe and Efficient Home Storage Systems | Karlsruhe Institute of Technology — June 2, 2015

Comments