Montreal — HPQ Silicon informed shareholders that further to its June 10 and August 18, 2021 releases, its technology provider, PyroGenesis Canada confirmed that, after all delays related to COVID-19, the last missing component, the power supply, has been delivered to PyroGenesis’ facility in Montreal.

PyroGenesis has begun the commissioning of the GEN3 PUREVAP™ Quartz Reduction Reactor (“QRR”) Pilot Plant.

PILOT PLANT TESTING TO VALIDATE PUREVAP™ QRR GAME-CHANGING ADVANTAGES

The PUREVAP™ QRR is a new innovative process, which will permit the one-step transformation of quartz (SiO2) into high purity silicon metal (>99.5% Si, referred to as 2N+) (patent pending #1) at reduced costs, energy input, and carbon footprint.

The central advantage of the process is its unique capability (patent pending #2) of continuously operating the unique carbothermic process, resulting in the early removal of impurities. Importantly, the process does not necessitate the extremely pure feedstock required by conventional processes to make standard purity Si (98.5% to 99.4% Si).

The process also requires 4.5 MT of raw material to make 1 MT of Silicon, versus 6 MT of conventional, a 25% reduction which potentially allows a 20% cash cost advantage versus the lowest cost producer using the traditional processes.

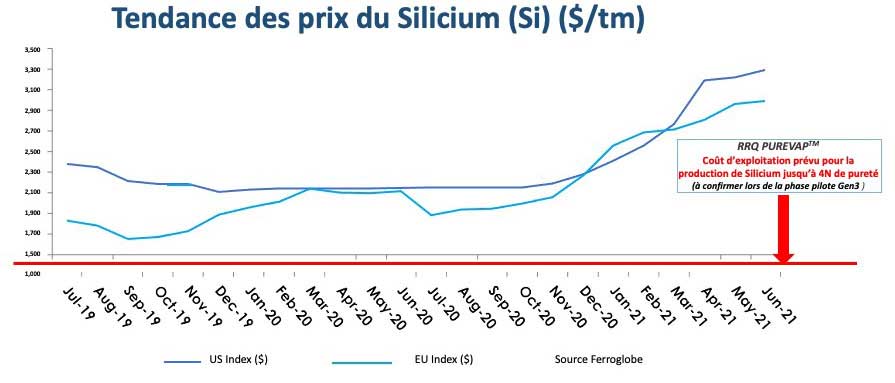

Figure 1) Silicon Metal pricing trends pre-Covid and now in the US and Europe, in relationship to the

PUREVAP™ QRR expected operating cost, that will be validated during the Gen3 pilot plant program.

SILICON MARKET DEFICIT AT 92,000 MT, PRICES SOARING, NEW GREENFIELD DEVELOPMENTS NEEDED

Recent market events are focussing attention on the fact that Silicon (Si), also known as silicon metal, is one of today’s key strategic energy metals needed to meet the goal of decarbonizing the economy by 2050.

High Purity Silicon (2N+) is in very high demand due to the underlying needs for Silicon as feedstock for Polysilicon (Solar and Electronics), the emerging Batteries sectors, and the more typical industrial Silicone applications, at a time when capacity is simply not available to meet demand.

This is a result of several of the old energy-intensive plants, mothballed during the Covid pandemic, being not economically or environmentally viable to return online. New greenfield projects will be needed to meet demand, and the PUREVAP™ QRR technology is well-positioned to eventually become the industry’s option of choice.

“HPQ has been at the forefront of Low-Cost Green Silicon innovation developments since 2015, and with the commissioning of the GEN3 PUREVAP™ QRR pilot plant, our timing couldn’t be better. With ESG principles playing an active role in materials sourcing, the world is waking up to the difficulty of securing the ESG compliant Silicon needed to meet its renewable energy goals. The reality of chronic underinvestment in new technologies combined with the offshoring of Silicon production capacity, has created a massive opportunity for HPQ and its PUREVAP™ QRR process, as we are the only company to bring to market a new process to make Silicon that is perfectly suited to the new demands and realities of the Silicon market,” said Mr. Bernard Tourillon, President and CEO of HPQ Silicon.

Comments