New ‘single-seed cast method’ for producing high quality monocrystalline solar cells has tremendous potential for the manufacture of low cost, high efficiency silicon solar cells.

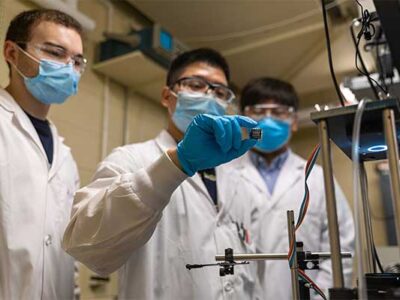

Researchers at MANA have developed the ‘single-seed cast method’ that is a new method of silicon casting. Compared with conventional casting, the new method enabled dramatic improvements in the crystalline quality of the silicon that are expected to improve the efficiency of silicon solar cells.

The conversion efficiency of silicon solar cells –that are the mainstream of commercial photovoltaics—is now going to reach 20% using single crystalline silicon. Increasing conversion efficiency is recent target for adding higher value to the solar cells. However, it is not possible to achieve such high efficiencies using conventional cast multicrystalline silicon.

Furthermore, since semiconductor grade single crystal silicon is too expensive for solar cells, there is strong demand for the development of a ‘third type’ of silicon as an alternative to multicrystalline and single-crystalline semiconductor silicon.

As a solution to this problem, a research team led by Takashi Sekiguchi, Group Leader of the Nano Device Characterization Group, Nano-Electronic Materials Unit, International Center for Materials Nanoarchitectonics (MANA), National Institute for Materials Science (NIMS), and Koichi Kakimoto, Professor of Kyushu University, has developed the so-called ‘single-seed cast method’ using a seed crystal for the silicon cast method.

The researchers succeeded in producing high quality, low impurity ingots of single crystal silicon (mono-silicon).

The new method consists of dissolving silicon feedstock inside a crucible and growing single crystalline silicon from a small seed. Notably, production costs can be reduced by this method compared with the method to produce dislocation-free single crystal silicon such as Czochralski method.

Importantly, solar cells produced using the new ingots yielded conversion efficiencies of 18.7%, which approach the value of 18.9% obtained with cells produced from semiconductor-silicon (CZ silicon) wafers.

In the future, further reductions of crystalline defects and impurities are expected to yield conversion efficiencies greater than 20 %.

Reference(s):

Publication: “Advantage in solar cell efficiency og high-quality seed cast mono Si ingot”, Y. Miyamura, H. Harada, K. Jiptner, S.Nakano, B. Gao, K. Kakimoto, K. Nakamura, Y. Ohshita, A.Ogura, S. Sugawara, and T.Sekiguchi, Applied Physics Express, 8, 062301 (2015)

Story: Seeding better efficiencies in monocrystalline silicon solar cells | International Center for Materials Nanoarchitectonics(WPI-MANA) — 4 Feb, 2016

Comments