TNO, TU Eindhoven, imec and TU Delft, partners in Solliance, joined forces to further push the conversion efficiency of tandem solar cells to beyond the limits of today’s commercial photovoltaic (PV) modules.

For the first time, four-terminal perovskite/silicon tandem devices with a certified top cell passed the barrier of 30%. Such high efficiency enables more power per square meter and less cost per kWh. The result is presented during the 8th World Conference on Photovoltaic Energy Conversion (WCPEC-8) in Milan, and it has been achieved by combining the emerging perovskite solar cell with conventional silicon solar cell technologies. The perovskite cell, which features transparent contacts and is part of the tandem stack, has been independently certified.

Additionally, achieving high-power density will create more opportunities to integrate these solar cells into construction and building elements, so that more existing surface area can be covered with PV modules. Breaking the 30% barrier is therefore a big step in accelerating the energy transition and improving energy security by reducing the dependency on fossil fuels.

The best of both worlds

Tandem devices can reach higher efficiencies than single junction solar cells because of a better utilization of the solar spectrum. The currently emerging tandems combine commercial silicon technology for the bottom device with perovskite technology, featuring highly efficient conversion of ultraviolet and visible light and excellent transparency to near infrared light.

In four-terminal (4T) tandem devices the top and bottom cells operate independently of each other, which makes it possible to apply different bottom cells in this kind of devices. Commercial PERC technology as well as premium technologies like heterojunction or TOPCon or thin-film technology such as CIGS can be implemented in a 4T tandem device with hardly any modifications to the solar cells. Furthermore, the four-terminal architecture makes it straight forward to implement bifacial tandems to further boost the energy yield.

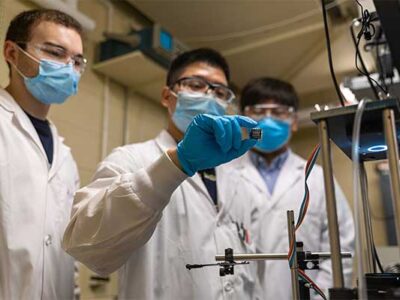

Researchers from the Netherlands and Belgium have successfully improved the efficiency of the semi-transparent perovskite cells up to 19.7% with an area of 3×3 mm2 as certified by ESTI (Italy). “This type of solar cell features a highly transparent back contact that allows over 93% of the near infrared light to reach the bottom device. This performance was achieved by optimizing all layers of the semi-transparent perovskite solar cells using advanced optical and electrical simulations as a guide for the experimental work in the lab,” says Dr. Mehrdad Najafi of TNO.

“The silicon device is a 20×20-mm2 wide, heterojunction solar cell featuring optimized surface passivation, transparent conductive oxides and Cu-plated front contacts for state-of-the-art carrier extraction” says Yifeng Zhao, Ph.D. student at TU Delft, whose results have been recently published in Progress in Photovoltaics: Research and Applications. The silicon device optically stacked under the perovskite contributes with 10.4% efficiency points to the total solar energy conversion.

Combined, 30.1% is the conversion efficiency of this non-area-matched 4T tandem devices operating independently. This world’s best efficiency is measured according to generally accepted procedures.

Future of four terminal tandem PV modules

This is not all: Combining this highly transparent perovskite cell with other silicon-based technologies, such as back contact (metal wrap through and interdigitated back contact cells) and TOPCon solar cells, has also delivered conversion efficiencies approaching 30%. This demonstrates the potential of highly transparent perovskite solar cells and their flexibility to be combined with already commercialized technologies.

These world best efficiencies obtained on a multitude of incumbent technologies is a further milestone towards industrial deployment. “Now we know the ingredients and are able to control the layers that are needed to reach over 30% efficiency. Once combined with the scalability expertise and knowledge gathered in the past years to bring material and processes to large area, we can focus with our industrial partners to bring this technology with efficiencies beyond 30% into mass production” says Prof. Gianluca Coletti, Program Manager Tandem PV technology and application at TNO.

—

Publication Referenced in the Article:

Yifeng Zhao et al, Effects of ( i )a‐Si:H deposition temperature on high‐efficiency silicon heterojunction solar cells, Progress in Photovoltaics: Research and Applications (2022). DOI: 10.1002/pip.3620

—

This article was written by Eindhoven University of Technology.

Comments