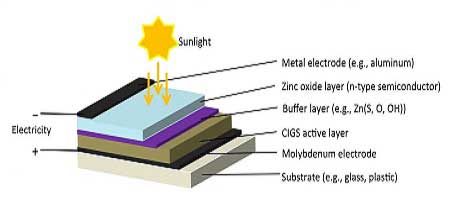

CIGS (copper-indium-gallium-selenide) solar cells are compound thin-film solar cells and the most established alternative to silicon solar cells. Solar conversion efficiencies of over 20% have recently been achieved in CIGS solar cells.

One of the factors known to strongly affect the conversion efficiency is the buffer layer. However, the structure of the buffer layer and its precise influence on the conversion efficiency have not been clarified.

Professor Masanobu Izaki and colleagues at Toyohashi University of Technology, in collaboration with researchers at the Research Center for Photovoltaic Technologies, National Institute of Advanced Industrial Science and Technology, have analyzed the structure of a zinc-based buffer layer in a CIGS solar cell at SPring8 (the world’s largest third-generation synchrotron radiation facility, located in Hyogo Prefecture, Japan).

“Performing structural analysis on very thin films is extremely difficult,” Professor Izaki said.

The researchers revealed the structure of the buffer layer and identified a way to improve the conversion efficiency. The study was published online in Progress in Photovoltaics on August 17, 2015.

“We analyzed the structure of the buffer layer by X-ray photoelectron spectroscopy, transmission electron microscopy, and other techniques. We found that the buffer layer was composed of two layers: an upper Zn(OH)2 layer and a lower Zn(S, O) layer. Moreover, the conversion efficiency was improved from 6.8% to 13.7% by removing the upper Zn(OH)2 layer,” Professor Izaki said.

In their article, the researchers described how to remove the upper Zn(OH)2 layer. The method is simple but impressive: quick immersion of a 120-nm-thick film in ammonia led to a doubling of the solar conversion efficiency.

This study reveals the importance of the buffer layer structure and composition, and is expected to be a valuable step for the development of next-generation CIGS solar cells. It is anticipated that once CIGS cells are able to be mass produced at reduced cost, they will become a main player in the solar cell market.

Reference(s):

Publication: Masanobu Izaki, Shinya Sugiyama, Tetsuhito Okamoto, Yuya Kusano, Takeshi Maki, Hironori Komaki, Hajime Shibata, Shigeru Niki. Structure of chemically deposited Zn(S,O,OH) buffer layer and the effects on the performance of Cu(in,Ga)Se2solar cell. Progress in Photovoltaics: Research and Applications, 2015

Story: Finding a way to boost efficiency of CIGS solar cells | Toyohashi University of Technology — September 28, 2015

Comments