Tesla battery day just wrapped up.

The main takeaway from the event was simple: Tera is the new Giga. The idea that — for the world to achieve a future where all forms of transportation are running on zero emissions and sustainable, we need to make a better battery and cheaper.

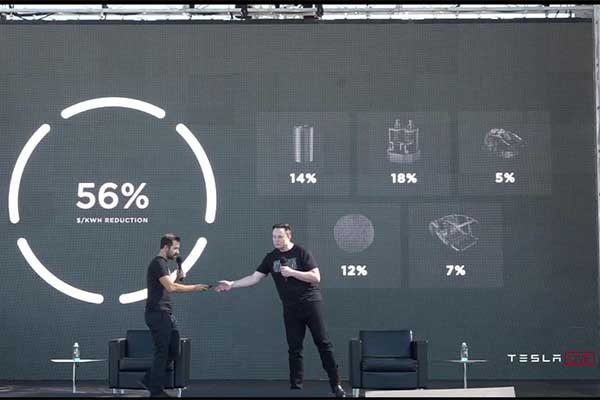

During the event, Tesla CEO Elon Musk revealed plans to cut battery costs by more than half and put the company on course to make an electric vehicle priced at $25,000 in about three years. Such an innovation would put Tesla vehicles on a par with petrol and diesel-powered vehicles.

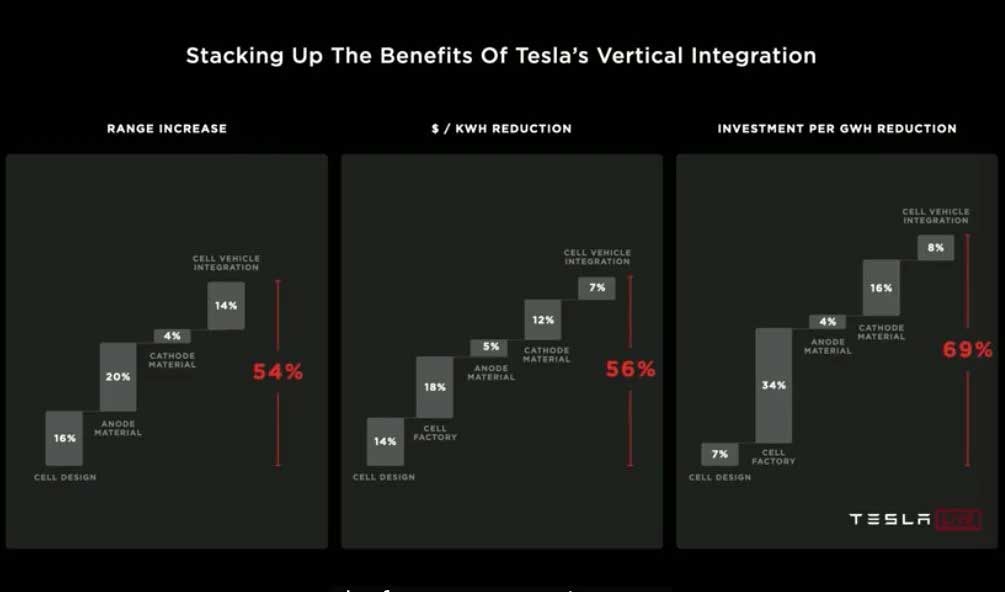

Tesla’s strategy will be based on a deeper vertical integration that will involve the company in every battery manufacturing level.

IMAGE: Screen capture from Tesla’s “Battery Day” presentation. A slide from Tesla’s Battery Day shows how several targeted improvements add up to significantly more competitive batteries.

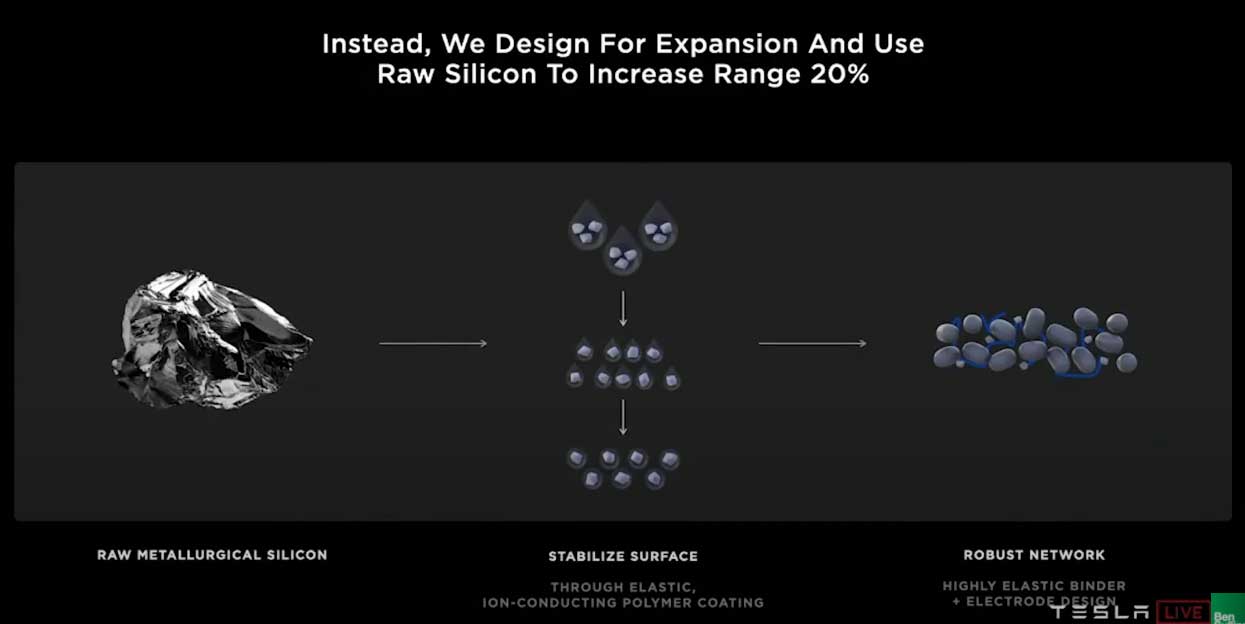

It will involve processing the raw materials and buying lithium deposits still in the ground and ultimately engineering its batteries from the ground up. It is also changing the battery chemistry by replacing the graphite in its batteries with high purity silicon.

Specifically, the anode is going to be made using silicon instead of graphite to contain lithium. According to Tesla’s engineers, the drive behind this is partly cost, silicon is exceptionally cheap compared with graphite, and partially because batteries with silicon-based anodes can also last significantly longer per charge.

But there is a problem with their current silicon technology.

“With silicon, the cookie crumbles and gets gooey,” said Elon Musk during the company’s battery day presentation. That gooeyness means that the material loses its energy retention and storage capacity. Every time a battery charges, the degradation means shorter life cycles for the battery.

IMAGE: Screen capture from Tesla’s “Battery Day” presentation. It showcases Tesla’s battery chemistry overhaul strategy by replacing the graphite in its anodes with silicon.

To solve this, Tesla said it will use cheap, metallurgical grade silicon and incorporate that into its new battery designs.

“What we’re proposing is a step-change in capability and a step-change in cost and to go to the raw metallurgical silicon itself,” said Baglino. “Design for it to expand [and] think of it in the electrode design … If you use simple silicon it is dramatically less than the silicon that is used in batteries today.”

Baglino expects that by using new treatment methods, the company could drop the cost to $1.20 a kilowatt-hour.

The new process involves using metallurgical silicon which not many companies have the process, nor expertise to produce effectively.

Luckily, there is one notable mention, HPQ Silicon. HPQ Silicon is a Montreal-based technology company that is developing new proprietary low-cost processes that can produce the metallurgical grade high purity silicon that battery manufacturers are looking for in one step and then transform that Silicon into spherical silicon powders.

The first process, called the PUREVAP™ Quartz Reduction Reactor (QRR) Project, has successfully produced, transformed, and purified quartz into high purity silicon metal (4N+ Si) in one step. In the second process, the PUREVAP™ Nano Silicon Reactor (NSiR) would enable the low-cost transformation of melted silicon into spherical nanopowders and nanowires. These spherical silicon metal nanopowders will allow the manufacturing of high-performance lithium-ion batteries using silicon metal anodes.

“Our technology can simplify and standardize the process used to convert quartz into silicon and then convert Silicon into nano-sized particles,” says Bernard Tourillon, HPQ Silicon’s CEO. “By doing this affordably, the market potential of silicon anode batteries and the products which could potentially utilize them could be vastly expanded.”

IMAGE: Screen capture from Tesla’s “Battery Day” presentation. Shareholders attend the Tesla meeting in their cars, like a drive-in movie.

This is one of many different technologies that Tesla could be in dire need of as it looks to reach the magic number.

Analysts describe the battery pack cost of $100 per kilowatt-hour (kWh) as the magic number, which was also laid out a decade ago by the U.S government. It is the cost at which a revolution of electric vehicle adoption can be plausible by reaching cost parity with internal combustion engine cars. Tesla’s battery prices in 2019 were $128/kWh, so the company’s 56% cost reduction would bring prices down to $56/kWh.

Musk is no stranger to glitzy and sometimes bizarre public demonstrations, but this time, the stakes are very high, especially as the number of competitors is mounting. To Tesla’s advantage, the goals set by its CEO during battery day are very achievable in the short term.

Comments