Sharp X-ray technology paves the way for a new technique to produce cheap, flexible and versatile double solar cells.

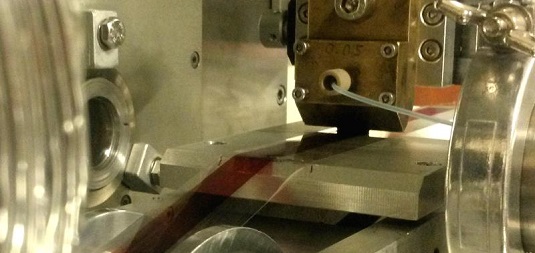

To accomplish this, scientists used a production process, where the different layers of a polymer (plastic) solar cell are coated from various solutions onto a flexible substrate. This way, the solar cell can be produced fast and cheap in a roll-to-roll process and in almost any desired length – up to several kilometres long single solar cell modules have already been manufactured.

In-Depth Article:

The sharp X-ray technology of DESY’s research light source PETRA III paves the way for a new technique to produce cheap, flexible and versatile double solar cells.

The method developed by scientists from the Technical University of Denmark (DTU) in Roskilde can reliably produce efficient tandem plastic solar cells of many metres in length.

The scientists used a production process, where the different layers of a polymer (plastic) solar cell are coated from various solutions onto a flexible substrate. This way, the solar cell can be produced fast and cheap in a roll-to-roll process and in almost any desired length – up to several kilometers long single solar cell modules have already been manufactured.

However, the energy harvesting efficiency of this type of solar cell is not very high. To increase the efficiency, a DTU team around Frederik C. Krebs stacked two such solar cells onto each other.

Each of these absorbs a different part of the solar spectrum, so that the resulting tandem polymer solar cell converts more of the incoming sunlight into electric energy.

But the multilayer coating presents several new challenges, as Andreasen explained: “Lab studies have shown that already coated layers may be dissolved by the solvent from the following layer, causing complete failure of the solar cell.” To prevent redissolution of the first solar cell, the scientists added a carefully composed protective intermediate coating between the two solar cells. The protective coating contains a layer made of zinc oxide (ZnO) that is just 40 nanometres thick – about a thousand times thinner than a human hair.

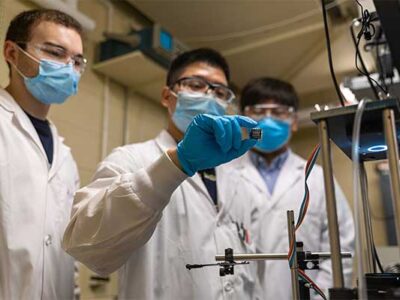

To check shape and function of the protective coating and the other layers of the tandem solar cell, the scientists used the exceptionally sharp X-ray vision of DESY’s research light source PETRA III that can reveal finest details. “The solar cell structure is very delicate, consisting of twelve individual layers altogether. Imaging the complete structure is challenging,” explained co-author Juliane Reinhardt from DESY’s experimental station P06 where the investigations were made. “And the sample was just two by four microns in size.”

Still, with the brilliant X-ray beam from PETRA III, the researchers could peer into the layer structure in fine detail, using a technique called 3D ptychography. This method reconstructs the three-dimensional shape and chemistry of a sample from the way it diffracts the incoming X-rays. For a full 3D reconstruction a great number of overlapping X-ray diffraction images have to be recorded from all sides and angles.

The advantage of ptychography is that it yields a higher resolution than would be possible with conventional X-ray imaging alone. And in contrast to electron microscopy, X-ray ptychography can also look deep inside the sample.

“With 3D ptychography, we were able to image the complete roll-to-roll coated tandem solar cell, showing, among other things, the integrity of the 40 nanometres thin zinc oxide layer in the protective coating that successfully preserved underlying layers from solution damage,” said DESY scientist Gerald Falkenberg, head of the experimental station P06. “These are the 3D ptychography measurements with the highest spatial resolution we have achieved so far. The results show that with the correct formulation of the intermediate layer, the underlying solar cell is protected from redissolution.”

The investigation paves the way to a possible industrial application of the new technique. “In a complex multilayer device like a polymer tandem solar cell, the device may fail in multiple ways,” Andreasen pointed out. “What we were able to see with 3D ptychography was that the preparation of the substrate electrode combines the good conductivity of a coarsely structured silver electrode with the good film forming ability of a conducting polymer that infiltrates the silver electrode and forms a smooth surface for the coating of the subsequent layers.” This is what allows the coating of very thin layers, at very high speeds, still forming contiguous layers, without pinholes.

Looking into the complete structure can also provide valuable information for a possible optimization of the device and the production process.

“In principle we make the devices without knowing what the internal structure looks like in detail. But knowing the structure tells us which parameters we can modify, and which factors are important for the device architecture, for example the special type of substrate electrode, and the formulation of the intermediate layer,” Andreasen explained.

“We were now able to verify that we can coat contiguous, homogeneous layers, roll-to-roll from solution, at speeds up to several meters per minute. We have shown that roll-to-roll processing of tandem solar cells is possible, with all of the layers roll-coated from solution, and that it is only possible using a specific formulation of the intermediate layer between the two sub-cells.”

The resulting polymer tandem solar cell converts 2.67 per cent of the incoming sunlight into electric energy, which is way below the efficiency of conventional solar cells. “The efficiency is low, compared to conventional solar cells, by a factor of 7 to 8, but one should consider that the production cost of this type of solar cell is several orders of magnitude lower than for conventional solar cells. This is the particular advantage of polymer solar cells,” explained Andreasen. “Furthermore, this is the first example of a roll-to-roll coated tandem solar cell where the efficiency of the tandem device actually exceeds that of the individual sub-cell devices by themselves.”

Publication Reference:

Henrik F. Dam et al: Enabling Flexible Polymer Tandem Solar Cells by 3D Ptychographic Imaging. Advanced Energy Materials, 2014.

Comments